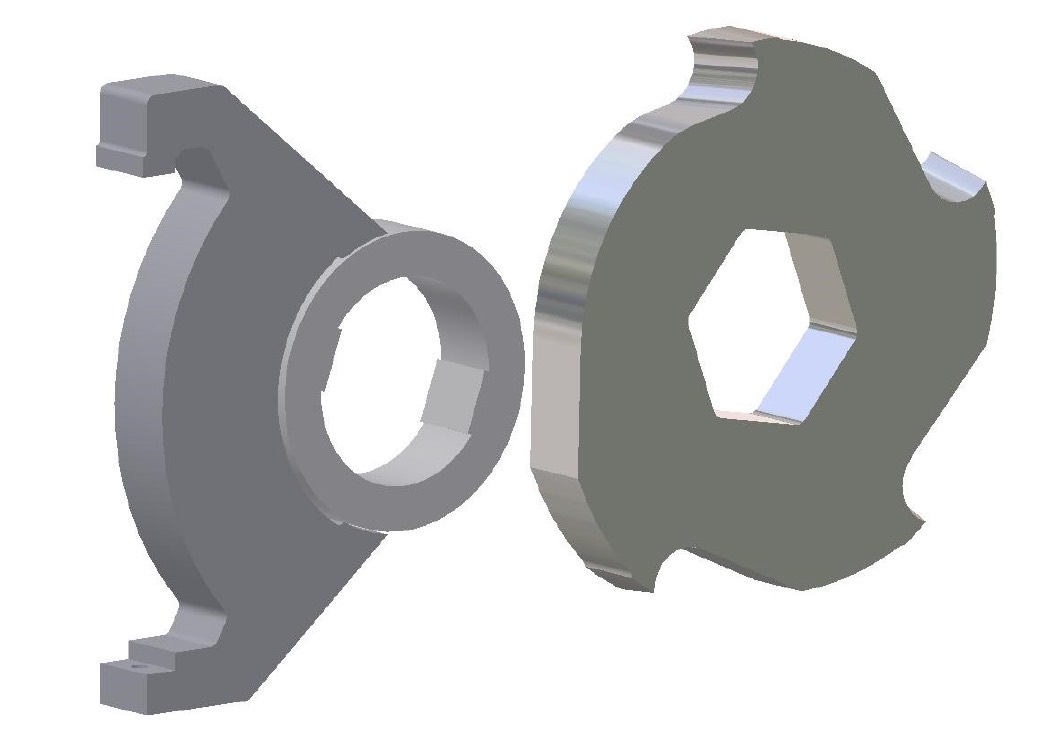

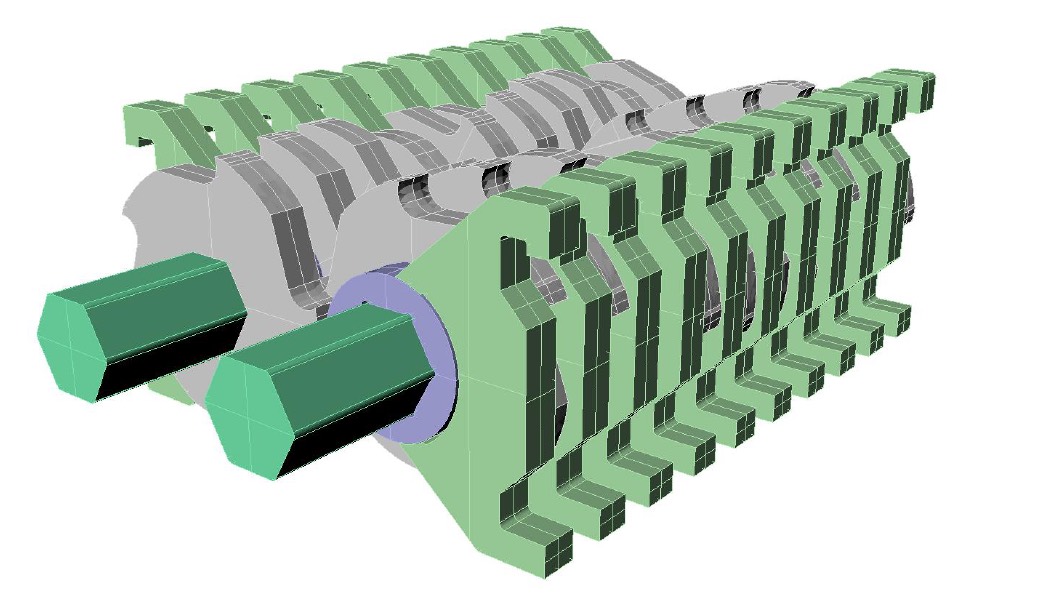

Slayer Blades supplies complete blades sets with spacer and cleaning sectors for industrial shredders of any brand, with 2, 3 or 4 shafts.

Blades are made of higher quality special steel featuring high wear resistance and toughness. Raw material origin is certified and guaranteed in compliance with strict technical specification.

Manufacturing process consists of tool machining with high precision CNC machine tools, followed by a special heat treatment which allows to reach the best balance between hardness and breaking strength, ensuring long lasting life.

Blades profile presents one or more hooks, depending on typology, shape and nature of the waste to be shredded. We can also supply special design blades according to customer requirements.

Blades for shredders

Our blades are suitable for most of waste processing, like paper, cardboard, plastic, WEEE, bulky waste,

special waste, hospital waste, industrial hazardous waste, tires, MSW, etc.

We can also take care of your worn shredder with re-sharpening service through surface grinding of blades, spacers and cleaning sectors. To compensate the gap that results in the shredding chamber after diminishing their thickness through grinding, new blades, spacers and cleaning sectors with suitable thickness are added to restore the original blade set length.

In case of damaged hooks, we can reshape them, if there is some material left over, bringing them back to the original gripping and aggressiveness.

Slayer Blades, with over 30 years of experience in special steel parts manufacturing, represents the ideal partner for supplying products with higher standard of reliability.

If you require a quotation or further information for any of our products and services please send us a mail to sb@slayerblades.it.